04

2024

-

02

Working principle of sandwich carriage plate hot press.

Working principle of sandwich carriage plate hot press

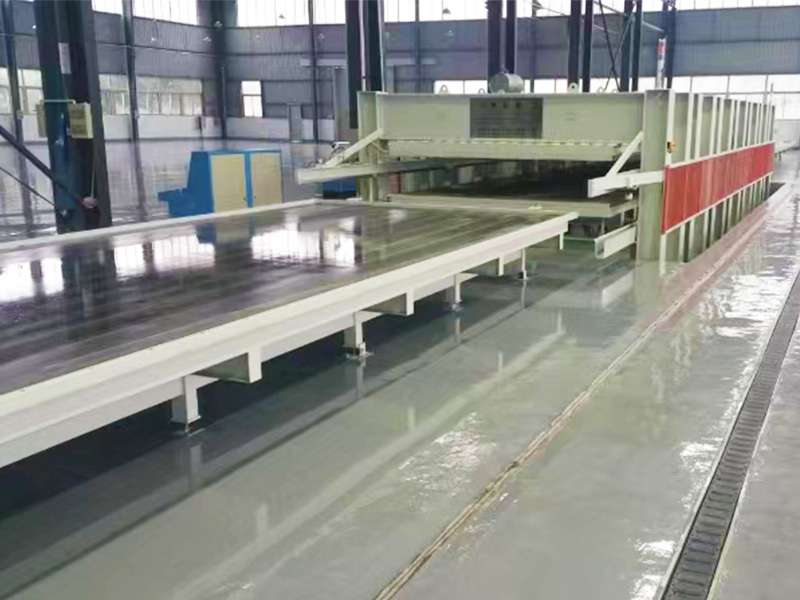

Sandwich carriage plate hot press is a mechanical equipment widely used in the carriage plate manufacturing industry. It utilizes high temperature and pressure to heat press and bond two layers of steel plates with a wooden core or PU foam material in the middle, forming a lightweight and high-strength composite material, namely the sandwich carriage board. Red Qi Machinery, a manufacturer of sandwich panel hot press, will provide a detailed introduction to the working principle of the sandwich panel hot press.

1、 Working principle

The sandwich carriage plate hot press mainly consists of heating system, pressure system, and control system. Its working principle is as follows:

1. Heating system: The heating system is the core part of the hot press machine, which is composed of electric heating elements and heating medium. During the hot pressing process, the electric heating element converts electrical energy into thermal energy and transfers the heat to the upper and lower heating plates through the heating medium, causing the heating plates to reach the set temperature.

2. Pressure system: The pressure system consists of a hydraulic cylinder and a pressure transmission mechanism. During the hot pressing process, the hydraulic cylinder transmits pressure to the upper heating plate through a pressure transfer mechanism, causing the upper heating plate to apply pressure to the lower heating plate. The adjustment of pressure is achieved through a hydraulic system to meet different process requirements.

3. Control system: The control system is the command center of the hot press machine, consisting of temperature controllers, pressure sensors, and displacement sensors. During the hot pressing process, the temperature controller controls the on/off of the heating element based on the difference between the set temperature and the actual temperature to maintain the temperature stability of the heating plate. At the same time, pressure sensors and displacement sensors monitor real-time changes in pressure and displacement to ensure the stability and reliability of the hot pressing process.

2、 Workflow

1. Preheating: Before hot pressing, the heating plate needs to be preheated to reach the set temperature. The preheating time is determined based on material and process requirements.

2. Bonding: After placing the two layers of steel plates and the core material in the middle as required, start the hot press machine, lower the upper heating plate, and bond with the lower heating plate.

3. Hot pressing: Perform hot pressing treatment at the set temperature and pressure. The hot pressing time depends on the material and process requirements. During the hot pressing process, the heating plate transfers heat to the core material and steel plate, causing them to bond together at high temperatures.

4. Cooling: After the hot pressing is completed, the heating plate continues to maintain pressure while undergoing cooling treatment. The cooling time depends on the material and process requirements. During the cooling process, the adhesive gradually solidifies and the strength of the sandwich compartment panel gradually increases.

5. Removal: When the temperature of the sandwich compartment board drops to room temperature, the upper heating plate rises and the finished product is removed. At this point, a complete hot pressing process has been completed.

3、 Features and Applications

The sandwich carriage plate hot press machine has the characteristics of high efficiency, energy conservation, and environmental protection. By adopting advanced heating technology and pressure control technology, it can quickly and accurately complete the hot pressing process, improving production efficiency. Meanwhile, the device uses environmentally friendly adhesives to reduce environmental pollution. In addition, it also has advantages such as easy operation and maintenance.

Sandwich carriage plate hot press is widely used in the carriage plate manufacturing industry, such as car carriages, train carriages, ship cabins, etc. By using sandwich panel hot press machines, enterprises can produce sandwich panel panels that are lightweight, high-strength, and corrosion-resistant, thereby improving the competitiveness of their products.

In summary, the working principle of the sandwich carriage plate hot press mainly involves processes such as heating, pressure application, and temperature control. Through precise control of these steps, high-quality sandwich compartment board products can be produced. This type of equipment has significant advantages in improving production efficiency, reducing costs, and meeting different application needs, providing strong support for the development of related industries.

Related News

SAF Coolest v1.3.1.2 设置面板 ARQSX-AGIG-SSAXE-ZWV

无数据提示

Sorry, the current section is being updated, stay tuned!

You can view other columns or return to the home page