25

2024

-

02

Common faults and troubleshooting methods of large plate negative pressure machine.

Common faults and troubleshooting methods of large plate negative pressure machine

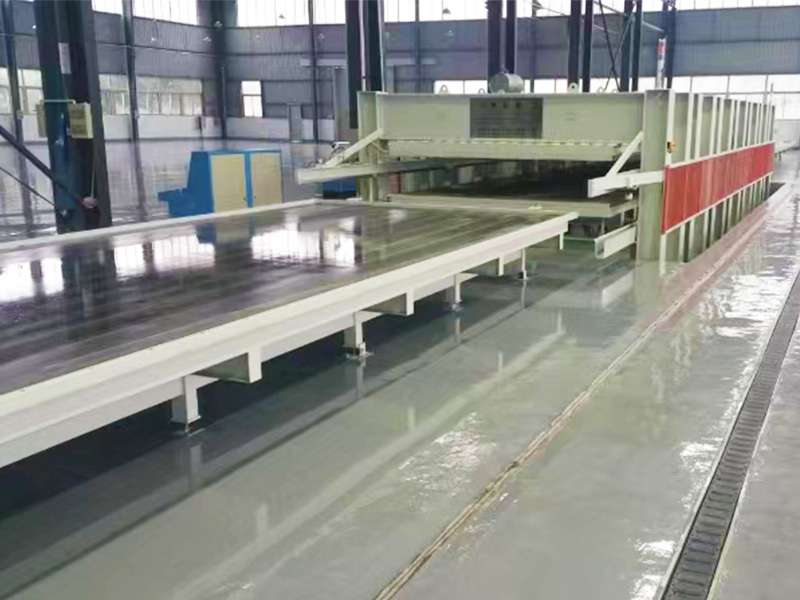

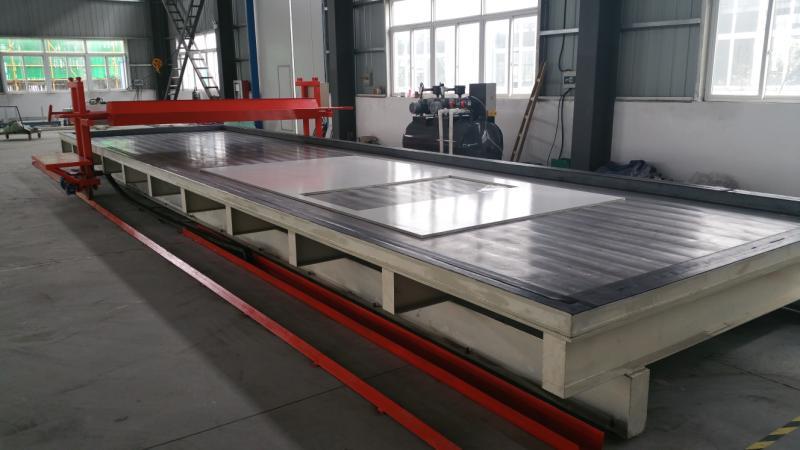

As an important equipment in modern industrial production, the stable operation of the large plate negative pressure machine is crucial for improving production efficiency and product quality. However, in actual use, the large plate negative pressure machine may encounter various malfunctions. This article will provide a detailed introduction to common types of faults and corresponding troubleshooting methods for large plate negative pressure machines, in order to help users better maintain and operate the equipment.

1、 Common types of faults in large plate negative pressure machines

Power failure: Power failure is one of the common faults in large plate negative pressure machines. Possible reasons include poor contact of the power circuit, damage to the power switch, and unstable power supply.

Vacuum system malfunction: Vacuum system malfunction may cause the large plate negative pressure machine to malfunction. Common faults include vacuum pump failure, vacuum pipeline leakage, vacuum valve failure, etc.

Hydraulic system failure: The hydraulic system of the large plate negative pressure machine is an important component, and common failures include hydraulic pump failure, hydraulic cylinder failure, hydraulic valve failure, etc.

Control system malfunction: Control system malfunction may cause the negative pressure machine of the large plate to malfunction or be inconvenient to operate. Common faults include PLC faults, touch screen faults, sensor faults, etc.

2、 Troubleshooting methods

Power troubleshooting:

Check if the power circuit has good contact, and if there is any poor contact, it should be repaired in a timely manner.

Check if the power switch is damaged, and replace it promptly if there is any damage.

Use a stable power supply to avoid voltage fluctuations affecting the equipment.

Vacuum system troubleshooting:

Check if the vacuum pump is working properly. If there is a malfunction, it should be repaired or replaced in a timely manner.

Check if there is any air leakage in the vacuum pipeline, and repair it in a timely manner.

Check if the vacuum valve is working properly. If there is a malfunction, it should be repaired or replaced in a timely manner.

Hydraulic system troubleshooting:

Check if the hydraulic pump is working properly. If there is a malfunction, it should be repaired or replaced in a timely manner.

Check if the hydraulic cylinder is damaged or leaking oil. If there are any problems, they should be repaired or replaced in a timely manner.

Check if the hydraulic valve is working properly. If there is a malfunction, it should be repaired or replaced in a timely manner.

Control system troubleshooting:

Check if the PLC is working properly, and if there is a malfunction, it should be repaired or replaced in a timely manner.

Check if the touch screen is damaged or malfunctioning. If there are any problems, they should be repaired or replaced in a timely manner.

Check if the sensor is working properly, and if there is a malfunction, it should be repaired or replaced in a timely manner.

3、 Troubleshooting precautions

Safety first: When troubleshooting, always follow safety operating procedures to ensure personal and equipment safety.

Accurate diagnosis: When troubleshooting, the cause of the fault should be accurately diagnosed to avoid blind disassembly and maintenance.

Use specialized tools: When troubleshooting, special tools and appropriate maintenance equipment should be used to avoid secondary damage to the equipment.

Record the repair process: When troubleshooting, the repair process and replaced components should be recorded in detail for future reference and maintenance.

4、 Summary and Outlook

As an important equipment in modern industrial production, the stable operation of the large plate negative pressure machine is crucial for improving production efficiency and product quality. By understanding and mastering the common types of faults and corresponding troubleshooting methods of large plate negative pressure machines, users can better maintain and operate the equipment, improve its service life and production efficiency. In the future, with the continuous progress of technology and changes in application requirements, the troubleshooting methods for large plate negative pressure machines will also be constantly updated and improved. Therefore, we need to constantly learn new knowledge and master new technologies to adapt to constantly changing market demands and technological developments.

Related News

SAF Coolest v1.3.1.2 设置面板 ARQSX-AGIG-SSAXE-ZWV

无数据提示

Sorry, the current section is being updated, stay tuned!

You can view other columns or return to the home page